Here's How To Maintain Your Bandsaw Blades

A worker is only as good as his tools. This saying speaks volumes about how crucial tools are to ensure efficient work. A metal or wood fabricator is no different. Access to the best tools and equipment can singlehandedly improve the fabricator’s productivity. A bandsaw is the most important tool in a metal shop or sawmill. This crucial equipment has simplified the seemingly complex cutting of thick metals and wood. Many parts together make bandsaws efficient. However, nothing is as important as a bandsaw blade. The blades must be kept in optimal condition to ensure consistency in cuts. In this blog, we list easy tips to ensure your bandsaw blade’s longevity.

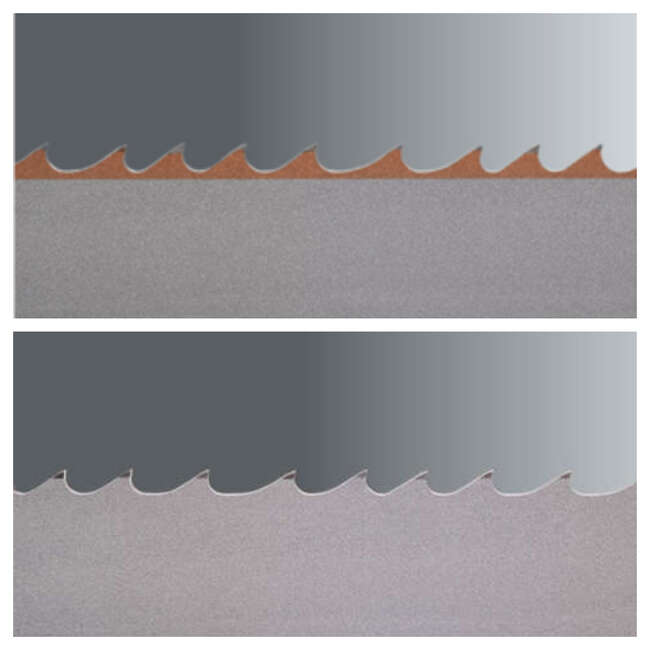

The Blade Is A Bandsaw’s Most Important Part

Proper Blade Selection

Improper blade selection is the primary cause of premature wear and tear. Choosing the right blade is the first step to ensuring its longevity. There are several blade manufacturers in the market. Not to mention the countless models they manufacture. Select the blade depending on the material you want to cut. If you use wood cutting blades to cut steel or vice-versa, the blade will most certainly be damaged.

Blade Tension & Feed Pressure

Getting the blade tension right is crucial to preventing damage to bandsaw blades. Higher tension causes the blade to flex more than needed. This compromises its performance and leads to dulling. Feed pressure refers to the rate at which the material is fed to the blade. You must not push the materials too hard on the blade to prevent friction and overheating. Using a good bandsaw lubricant helps deal with friction.

Conclusion

Industrial Bandsaw Services in Mississauga, Ontario supplies the best bandsaw blades. Our extensive selection features blades from the best brands. We also supply brand-new vertical and horizontal bandsaws. Call (905) 566-4800 to get your hands on the best bandsaw supply in Ontario.