Sawmills Blades in Canada For Harsh Operating Conditions

Sawmills in Canada present unique challenges that demand precisely crafted, high-performance tools. Extreme temperature fluctuations, denser wood species, and extended production cycles require mills to use sawmill blades in Canada engineered specifically for harsh working environments. Choosing the right bandsaw blades has a direct impact on productivity, cut quality, and long-term operational efficiency.

What Makes Canadian Sawmill Conditions More Demanding?

Canadian sawmills operate in environments where cold weather and heavy workloads are common. Blades must perform consistently in freezing temperatures, resist corrosion from moisture, and handle continuous cutting without compromising accuracy. Dense hardwoods and resin-heavy softwoods also place additional stress on cutting edges, increasing the risk of wear, breakage, and tooth damage if blades are not designed to handle these demands.

How Do Harsh Conditions Affect Blade Performance?

When blades are not built for demanding conditions, mills often experience premature dulling, inconsistent cuts, and frequent blade failures. Temperature changes can affect blade tension and stability, while moisture can lead to corrosion and material fatigue. Over time, these issues result in reduced cutting accuracy, increased downtime, and higher blade replacement costs—negatively impacting overall production output.

What Features Should Sawmill Blades in Canada Have?

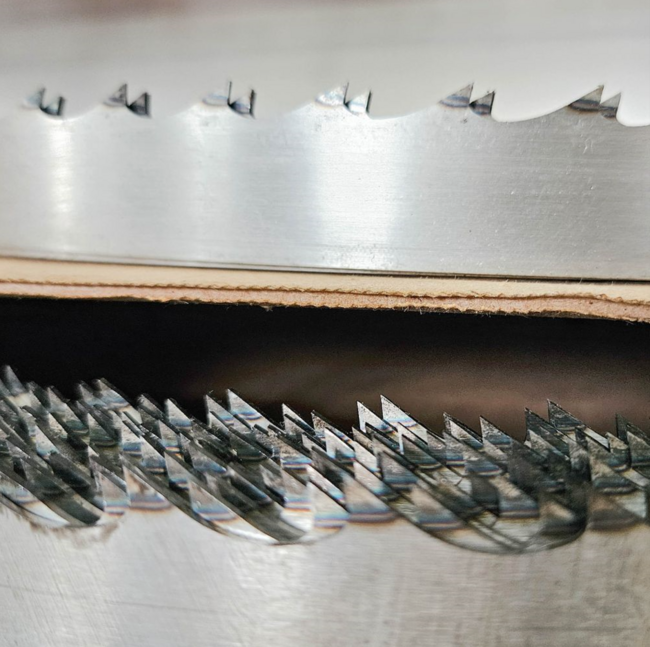

To perform reliably in Canadian environments, sawmill blades must be manufactured with durability and precision in mind. Key features include:

- High-quality steel for improved strength and flexibility

- Precision-ground teeth for consistent cuts

- Heat-treatment for longer blade life

- Reduced cracking, wear, and corrosion

- Consistent performance under fluctuating temperatures

These design elements ensure blades maintain accuracy and structural integrity throughout demanding projects.

Why Does Blade Quality Directly Impact Productivity?

High-performance sawmill blades in Canada reduce downtime caused by blade changes, the need for sharpening, or breakage. Stable cutting accuracy improves yield, minimizes waste, and ensures product quality. For sawmills in Canada, reliable blades mean smoother operations, more efficient resource utilization, and lower operating costs.

Why Choose Industrial Bandsaw Services for Sawmill Blades in Canada?

Industrial Bandsaw Services is a trusted supplier of sawmill blades in Ontario, providing products built to withstand the harshest operating conditions. With our focus on quality, precision, and performance, we provide Canadian mills with blades designed for durability, efficiency, and consistent yield. We help your sawmill operate at peak productivity, even in the most challenging environments. Our extensive product selection also features the best Hydmech bandsaws. Call 905 566 4800 to get a free quote today.

FAQs:

What type of sawmill blades work best in Canadian conditions?

Sawmill blades made from high-quality steel with precision-ground teeth and proper heat treatment perform best in Canada’s cold, high-moisture, high-load environments.

How do harsh weather conditions affect sawmill blade performance?

Cold temperatures, moisture, and dense wood species can cause faster dulling, corrosion, tension issues, and blade fatigue if blades are not designed for extreme conditions.

Where can I buy reliable sawmill blades in Canada?

Industrial Bandsaw Services in Mississauga, Ontario, is a trusted supplier of high-performance sawmill blades built specifically for Canadian operating conditions.