Three Safety Precautions When Working with a Wood Bandsaw Blade

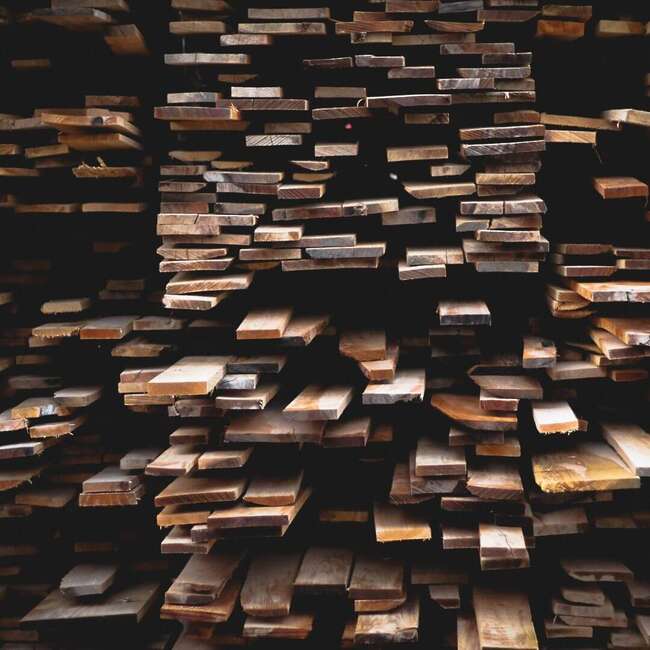

The way sawmills operate has radically changed in recent decades. From using conventional handmade tools, sawmills have switched to motorized saws that can cut even the thickest log to lumber with ease. This highlights that a bandsaw is clearly at the center of the revolution witnessed among sawmills. However, if we look closely, we will understand that the bandsaw blade is in fact the most important aspect of a bandsaw. Wood bandsaw blades are sharp, durable, and strong, making it easy for sawmill owners to cut through wood with ease. Since it is extremely sharp, operators must practice caution while working with bandsaw blades. In this blog, we list three safety precautions that bandsaw operators must practice while working with a wood bandsaw blade.

-

Matching Blade Width to Desired Cut Radius

When it comes to achieving precise cuts on a wood bandsaw, matching the blade width to the desired cut radius is key. The width of your blade will determine how tightly you can turn and navigate corners during the cutting process. If you're aiming for sharp, intricate curves, opting for a narrower blade is recommended. This allows for better maneuverability and control as you guide the material through the saw's path, thus lowering the chances for any untoward incidents.

-

Considering Material Thickness when Choosing TPI

The TPI (teeth per inch) of the blade is crucial in determining its efficiency and effectiveness. For thinner materials, such as plywood or veneer, a higher TPI is recommended. This allows for smoother cuts and minimizes any chance of chipping or splintering. On the other hand, when dealing with thicker hardwoods or rough lumber, a lower TPI can handle the task better by removing more material with each tooth. Choosing a blade with incorrect TPI can lead to unwanted vibrations and make it difficult for the operator to use the bandsaw.

-

Ensuring Proper Blade Length

Determining the correct blade length is essential for maintaining stability and preventing unnecessary strain on your machine. Using a blade that is too short may result in limited cutting capacity or even damage to both the material and the saw itself. On the other hand, using a blade that is too long can lead to excessive vibration and decreased control over your cuts. Prioritizing these precautions will not only enhance safety but also increase productivity and overall satisfaction with each woodworking project you undertake!

Conclusion

Remember, safety should always be your top priority when operating any power tool like a bandsaw. Always wear protective gear such as goggles and gloves, keep your workspace clean, and follow manufacturer instructions carefully. Apart from the risk factors listed above in this blog, one of the biggest risks to bandsaw operators comes from using low-quality bandsaw blades. You can rely on Industrial Bandsaw Services for the best wood bandsaw blades from Kasco. The blades we supply are sturdy and durable, meaning they won't break or vibrate. Contact our team to learn about the wide range of bandsaw blades we offer.