What to Look for in Reliable Sawmill Blades

Productivity and cut quality are of paramount importance in the wood processing industry. And these are heavily dependent on the blade. Whether you’re running a high-volume sawmill or a specialized cutting operation, the performance of your equipment is only as good as the sawmill blades you use. Poor blade quality leads to inconsistent cuts, excessive downtime, and higher operating costs, which is why choosing reliable sawmill blades is not just a purchase decision but a long-term investment. With deep industry knowledge and hands-on service experience, Industrial Bandsaw Services in Mississauga, Ontario, brings you this blog to help you understand what truly matters when selecting sawmill blades.

What Makes a Sawmill Blade Reliable?

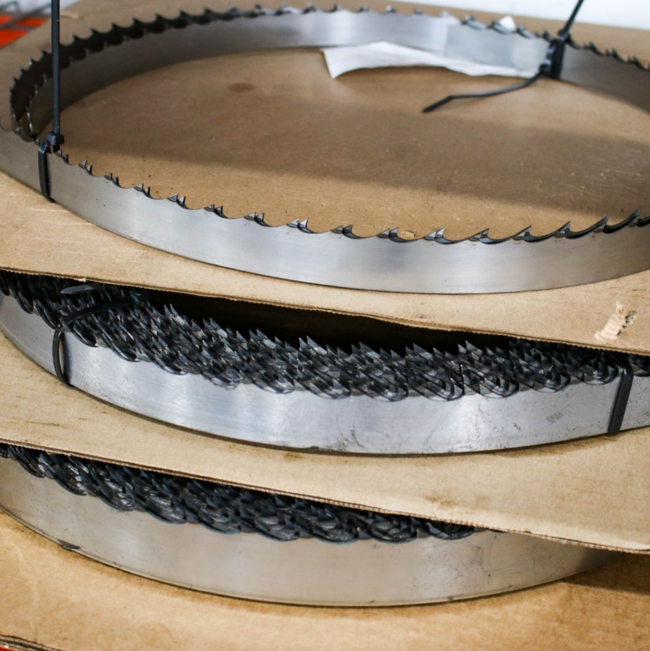

A reliable sawmill blade is engineered to deliver consistent cutting over extended periods. It is made of high-quality steel, precise tooth geometry and controlled heat treatment to ensure strength, flexibility, and wear resistance. Sawmill blades are known to maintain sharpness, resist cracking, and perform consistently across varying wood types and operating conditions.

What Should You Consider Before Sourcing Sawmill Blades

Blade Material and Construction

The blade material determines its durability. Steel blades offer the right balance between hardness and flexibility, allowing them to withstand cutting stress while avoiding breakage and deformity. Construction factors such as uniform tooth spacing, proper set, and accurate welding also play a major role. Poor construction can lead to vibration, uneven cuts, and premature blade failure.

Tooth Design/Geometry

Tooth geometry influences how efficiently sawmill blades cut through wood. The right tooth profile improves chip removal, reduces heat buildup, and provides smoother cuts. Different applications require different tooth designs. It usually depends on wood species, moisture content, and cutting speed. Selecting the correct tooth configuration helps maximize blade life and cutting accuracy.

Maintenance and Support From the Manufacturer

Sawmill blades require proper maintenance to perform at their best for the longest. Reliable suppliers offer sharpening, re-tipping, and repair services to extend blade life and maintain consistent performance. Look for manufacturers with access to technical support and expert advice.

Why Choose Industrial Bandsaw Services for Sawmill Blades?

Industrial Bandsaw Services in Mississauga, Ontario, distributes new and refurbished bandsaws. We also supply blades, coolants and parts from Hyd Mech, Kasco, Eberle, Simmons and Scotchman. We provide 24/7 emergency service calls and custom blade fabrication for all makes and models. Call 905 566 4800 today if you are seeking quality bandsaw supplies.

FAQs

How often should sawmill blades be replaced or sharpened?

Blade life depends on usage, wood type, and maintenance. Regular sharpening helps extend blade life and maintain cut quality.

Can one sawmill blade type handle all wood species?

Not always. Different wood types may require specific blade materials or tooth designs for optimal performance. Contact Industrial Bandsaw Services in Mississauga, Ontario, for guidance.

Do reliable sawmill blades reduce operating costs?

Yes. High-quality blades last longer, cut more efficiently, and reduce downtime, lowering overall operating costs. You can count on Industrial Bandsaw Services in Mississauga, Ontario, to source reliable sawmill blades at the best rates.